This blog delves deeper into the transformative power of intelligent freight visibility. It highlights the impact of enhanced visibility on overall supply chain operations. It also explores how artificial intelligence unlocks a world of possibilities and enables a digital supply chain.

1. Overview of Intelligent Freight Visibility

The global logistics industry has evolved with rapid technological innovations and the emergence of digital technologies. For decades, traditional freight visibility has been the compass guiding organizations through the complex world of supply chains. It provides basic location tracking and a glimpse into the whereabouts of our precious freight. But in today’s hyper-connected, data-driven world, the focus has shifted beyond simple shipment status and estimated arrival times. Businesses now require real-time information, including freight conditions and location, to navigate the complexities of digital supply chains.

Enter Intelligent Freight Visibility!

It goes far beyond the “where” of traditional methods. It delves into the “why” and “when” by leveraging the power of artificial intelligence (AI) and unlocking a treasure trove of data-driven insights. Intelligent freight visibility builds upon basic tracking by incorporating data analytics and AI. This allows for a more comprehensive understanding of the shipment’s journey. Actionable insights on off-schedule shipments help shippers make more informed decisions across the supply chain, improving operational planning, procurement operations, and performance benchmarking while enhancing customer experience and delivering risk-mitigation strategies.

Let’s dive deeper into intelligent freight visibility and explore real-world examples of how businesses leverage this powerful technology to gain a competitive advantage.

2. Flying Without a Compass: Challenges of Limited Freight Visibility

Building resilient supply chains is crucial in the face of adversity. To achieve this, companies require access to predictive and real-time data regarding the location of assets, order processing, inventory, delivery, and possible supply chain disruptions. However, traditional methods of gaining visibility in supply chain operations are insufficient in today’s digital era. Without proper visibility, organizations face numerous challenges:

- Customer Churn:

Customer churn is a significant challenge in today’s supply chain management process. However, limited data analytics capabilities can worsen this problem by hampering operational visibility. According to studies conducted by the Aberdeen Group, companies with solid supply chain visibility experience 33% lower customer churn rates. This transparency enables businesses to identify and address issues such as delayed deliveries or inaccurate order fulfillment before they lead to customer frustration and churn.

- Delayed Deliveries:

Delayed deliveries are a supply chain thorn, but data analytics can be your rose. A study by McKinsey & Company found that companies leveraging advanced analytics for logistics reduced delivery times by an average of 10%. Businesses can predict and prevent bottlenecks by analyzing past delays, traffic patterns, and real-time data, ensuring your products arrive on time.

- Increasing Overhead Costs

Soaring overhead costs are a constant concern. But a hidden culprit is lurking in the shadows: the lack of data analytics. Imagine operating blindfolded – that’s what happens without data. Inefficiencies like excessive warehousing due to poor inventory management, unnecessary transportation routes chosen by gut feeling, and inflated costs from blindly accepting supplier quotes all become invisible. These loopholes leak profit silently, as you lack the insights to optimize resource allocation, negotiate better rates, or implement preventive maintenance to minimize downtime.

- Increasing Transportation Risks

Operating a supply chain without real-time data creates significant risks. An American Transportation Research Institute (ATRI) study found that congestion cost trucking a record $94.6 Billion in 2021. Lacking data on weather, traffic, or potential equipment issues hinders proactive action, leaving shipments vulnerable to disruptions and missed deliveries.

Furthermore, inefficient routes pose a hidden danger. Relying solely on outdated information or intuition for route selection can lead to congested paths, increasing risks of accidents, breakdowns, and product damage.

Intelligent freight visibility is critical to better-anticipating supply chain issues and mitigating them with the right operational processes.

3. Hyperdrive Supply Chain with The Power of AI in Intelligent Freight Visibility

AI adoption in supply chain operations is progressing cautiously, unlike the rapid innovation seen in creative fields with tools like ChatGPT. However, experts anticipate a future where AI, combined with advanced data analytics, can streamline operations, and significantly reduce human intervention within the supply chain. Here’s how AI can inject intelligence into the process:

3.1 Turning Data into Actionable Insights

- Real-Time Analysis: AI can analyze vast amounts of data from various sources (GPS, weather reports, traffic data, customs documents) in real-time. This allows for continuous monitoring and identification of potential disruptions before they escalate.

A study by McKinsey found that companies that leverage advanced analytics in their supply chains can achieve cost reduction of up to 10%. – McKinsey & Company

- Predictive Analytics: AI can leverage historical data and real-time factors to predict potential risks associated with specific routes, delays, equipment shortages, or potential regulatory hurdles. This empowers proactive planning and alternative solutions.

3.2 Optimizing Logistics Operations

- Dynamic Route Optimization: AI can analyze real-time traffic conditions, weather patterns, and even historical delays to suggest the most efficient shipping routes, considering factors like fuel consumption and driver fatigue.

- Automated Alerts and Notifications: AI can identify deviations from planned routes or unexpected delays and trigger automated alerts to relevant stakeholders (shippers, carriers, customers). This facilitates faster response and minimizes downtime.

- Automated Exception Handling: AI can analyze shipment data and identify potential issues like missing paperwork or regulatory roadblocks. It can then trigger automated workflows to expedite resolution, minimizing delays.

3.3 Enhancing Customer Experience

- Predictive ETAs: AI can analyze data to predict Estimated Time of Arrivals (ETAs) more accurately, allowing for proactive communication with customers about potential delays.

- Improved Communication: AI-powered platforms can automate customer communication, providing real-time updates and proactively addressing concerns.

- Transparency and Trust: Intelligent freight visibility powered by AI fosters customer trust by providing precise and consistent information about their shipments.

- Freight Audit & Pay: AI can provide information about when shipments were delivered or any dwell or detention times to help calculate invoices and penalties, accurately and quickly improve cash flow in the supply chain, and reduce appeals and negotiations.

4. The Strategic Role of Intelligent Freight Visibility in Optimal Rerouting

The recent collapse of the Francis Scott Key Bridge in Baltimore has caused major disruptions in the trucking industry. There may be a temporary shortage of truckers, which will drive costs up. Direct and indirect costs will increase by 20%-30% on specific trade lanes in the short term. Trucks play a vital role in American commerce, and the closure of a central transportation hub on the East Coast has led to significant challenges. Rerouting around the damaged bridge has resulted in hundreds of extra miles added to journeys, leading to congestion on already busy roads. According to the American Trucking Association, around 3600 trucks passed the bridge daily before its collapse. Assuming an average detour adds 100 miles, an additional 360,000 miles are driven daily, significantly impacting trucking companies’ fuel costs. Also, trucks are spending more time on the road, stuck in traffic and the delay is causing missed deliveries and creating potential stockouts.

Intelligent freight visibility emerges as a strategic weapon for optimal rerouting in such scenarios.

Here’s how:

- Real-time Tracking and Route Optimization: Intelligent freight visibility systems provide real-time location data on every shipment. According to a American Transportation Research Institute study, traffic congestion costs the trucking industry billions of dollars annually. Roadrunner Transportation Services, a prominent American trucking firm, uses such a system. During the bridge closure, Roadrunner’s dispatchers could analyze real-time traffic data and reroute trucks carrying essential medical supplies to avoid congestion, ensuring timely hospital deliveries.

- Data-Driven Decision Making: Intelligent visibility goes beyond just tracking. Advanced systems analyze historical traffic patterns and combine them with real-time data to predict congestion hotspots. During the bridge closure, Project44 (a leading visibility provider) used AI to analyze historical traffic patterns around Baltimore and predict future congestion zones. This data then suggested the most efficient detour routes, saving the company significant resources.

5. Future Trends and Innovations in Supply Chain Visibility

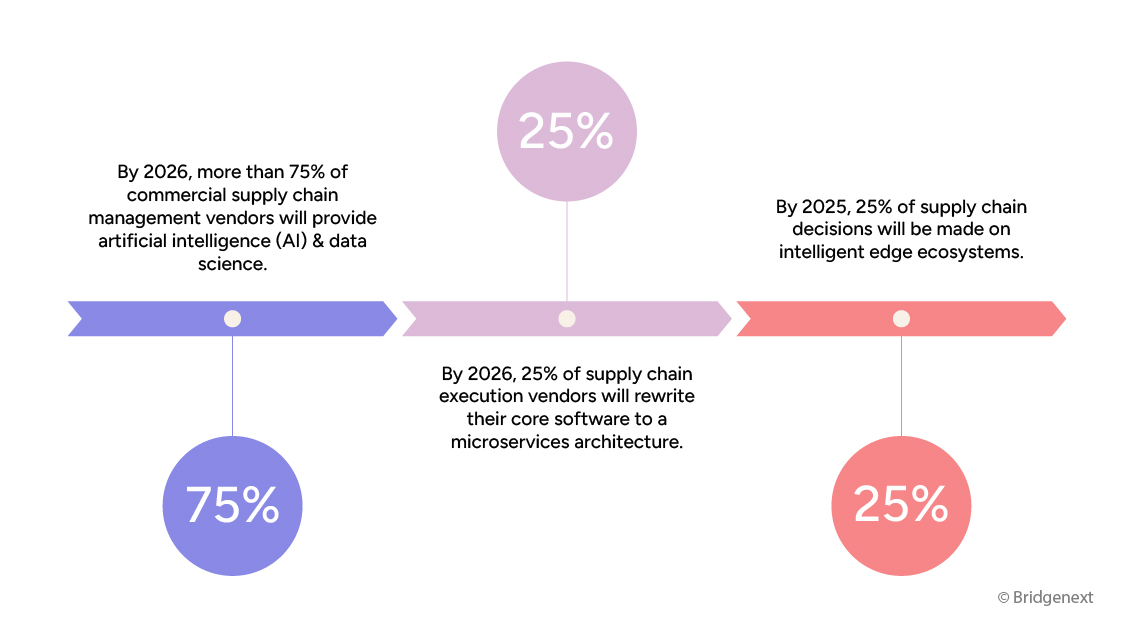

The future of intelligent freight visibility is about leveraging advanced technologies to gain real-time, end-to-end transparency across your entire supply chain operations. According to Gartner, 80% of large organizations will leverage advanced AI, ML, and IoT capabilities by 2026. Organizations will incorporate these innovations for even richer insights and automation, including:

- Digital Supply Chain Twins: This concept involves creating a digital replica of your physical supply chain. By integrating real-time data from various sources, the digital twin can simulate different scenarios and predict the impact of disruptions or changes in strategy. This allows for better risk mitigation, improved planning, and optimization of your entire supply chain network.

Source: Appinventive

- Focus on Sustainability: Consumers are becoming increasingly conscious of the environmental impact of products. Supply chain visibility will play a crucial role in ensuring sustainable practices. By tracking the origin of materials, energy consumption during transportation, and waste generation, companies can identify areas for improvement and demonstrate their commitment to sustainability.

- The Emergence of Specialized Visibility Solutions: As supply chains become more complex and specialized, we might see the rise of industry-specific visibility solutions. These solutions would cater to the unique needs of different sectors like pharmaceuticals, perishables, or high-value goods, providing tailored features and functionalities.

- Rise of Data Aggregators: Imagine a central hub that collects data from disparate sources like TMS, freight visibility platforms, IoT sensors, and carrier systems. This is where data aggregators come in. They will use advanced algorithms to analyze this vast data, providing actionable insights for improved decision-making, contingency planning, and proactive problem-solving.

6. The Dynamic Duo: Enhancing Logistics with Freight Visibility and TMS

Freight tech is critical for remaining competitive, and supply chain leaders have long recognized the value to be gained from it. However, when organizations aim to go digital, they often tackle projects requiring new systems and technologies.

A report from Verte Research reveals that customers are obsessed with other tracking, as 90% of customers track their package during shipping, with 20% monitoring progress multiple times a day.

Transport management systems (TMS) are crucial for logistics teams to ensure efficient transportation, planning, execution, and optimization of goods movement throughout supply chains. However, the ROI from implementing a TMS can only be genuinely maximized when paired with a real-time visibility solution, and as a result, choosing an experienced provider in parallel to a TMS can fast-track these benefits.

6.1 Benefits of Implementing Intelligent Freight Visibility in Parallel With TMS

There are several benefits to implementing freight visibility alongside a TMS:

- Reduced Detention & Demurrage Charges: Real-time tracking allows for proactive communication with carriers and facilities to avoid delays and associated detention or demurrage charges that can significantly inflate transportation costs.

- Demand Forecasting: Freight visibility data, combined with TMS insights into shipment lead times, can be used for more accurate demand forecasting. This allows you to optimize inventory levels, reducing the risk of stockouts or overstocking.

- Automated Workflows: Integration eliminates the need for manual data entry between systems, reducing errors and streamlining workflows. This frees up staff for higher-value tasks.

- Improved Resource Allocation: Real-time shipment data allows for better resource allocation, such as dock scheduling and labor planning, based on actual arrival times.

- Data-Driven Decisions: The combined data from TMS and freight visibility provides a comprehensive picture of your transportation performance. This allows you to identify areas for improvement and track progress over time with clear metrics.

7. Tomorrow’s Vision: Intelligent Freight Visibility Paving the Way for the Future

Intelligent freight visibility is gaining momentum and has moved to the priority list of many organizations due to customer demand, supply chain disruptions, and the necessity to optimize costs in decision-making for inventory management.

Bridgenext (formerly Emtec Digital) offers a range of services and solutions to help companies navigate the journey toward the future of digital supply chain. We understand the importance of staying ahead in a rapidly evolving industry, and our expertise in emerging technologies allows us to help organizations achieve their age-old objectives of ‘better efficiency’ and ‘increased margins.’ With Bridgenext, you can achieve digital realization through the latest technology customized per your needs and requirements.

Contact Bridgenext to harness the potential of intelligent freight visibility and take a proactive step toward gaining a competitive edge.

References

www.prnewswire.com/news-releases/trucking-industry-asked-to-rank-top-concerns-301911405.html

www.mckinsey.com/insights/operations/taking-the-pulse-of-shifting-supply-chains

www.ttnews.com/articles/congestion-costs-atri

www.project44.com/for-carriers/carrier-faq

www.ttnews.com/articles/baltimore-trucking-shipping

appinventiv.com/blog/technology-in-supply-chain-management/

https://www.gartner.com/en/articles/gartner-predicts-the-future-of-supply-chain-technology