Hurricane season is a recurring challenge for transportation and logistics companies, threatening supply chain stability and operational efficiency. Recent storms like Hurricanes Helene and Milton have showcased how these natural events can disrupt even the most resilient supply chains.

For industry leaders, preparing for these potential disruptions is crucial to maintaining business continuity. Here’s a guide to help logistics professionals brace for the storm and protect their supply chains during the remainder of hurricane season and beyond.

Understanding the Threat: Hurricanes and Supply Chain Vulnerabilities

While hurricanes primarily impact coastal areas, the ripple effects can spread across the supply chain network, causing extensive delays and disruptions. When hurricanes like Milton make landfall, they damage infrastructure, interrupt transport routes, and halt production lines, often leading to a domino effect across global supply chains. For instance, Hurricane Helene alone led to over 1,000 flight cancellations and temporarily closed two major ports, halting goods movement and significantly impacting trade value. In preparing for hurricane season, logistics professionals must understand the potential scope and scale of these impacts to build a resilient strategy.

How Hurricanes Disrupt Supply Chains

-

Transportation Delays and Route Closures

Hurricanes often close down ports, delay flights, and render roads impassable. Transportation networks are among the first to feel the impact, which leads to immediate bottlenecks and delivery delays across distribution channels.

-

Inventory Challenges and Stock Shortages

Weather-related disruptions can prevent the timely delivery of raw materials, leaving companies with insufficient stock to meet demand. This affects production lines and can force businesses to adjust inventory levels on the fly.

-

Financial Implications

In addition to logistical challenges, hurricanes bring significant financial strain. Increased transportation costs, potential damage to goods, and labor disruptions make it essential for companies to include these risks in their financial planning.

Lessons from Hurricanes Helene and Milton

Analyzing recent storms like Helene and Milton provides valuable insights into the scale of potential impacts. By understanding the specific ways these hurricanes affected global logistics, companies can anticipate similar scenarios and be better prepared.

- Transportation Networks: Flooded routes and closed ports from these hurricanes highlighted the need for contingency plans in route management and alternative transportation options.

- Inventory and Stock Levels: Helene, for example, caused raw material delays, illustrating the importance of proactive inventory management and emergency sourcing options.

Preparing for the Storm: Key Mitigation Strategies for Supply Chain Leaders

The good news is that there are effective strategies to mitigate weather related disruptions. Technology, data-driven insights, and proactive planning can help transportation and logistics companies maintain a smooth flow, even during storm season.

-

Enhance Real-Time Supply Chain Visibility

Real-time tracking systems allow businesses to monitor shipment locations, manage inventory, and rapidly adapt to changes in the supply chain. Transparency across the logistics network ensures that teams can respond to challenges swiftly.

-

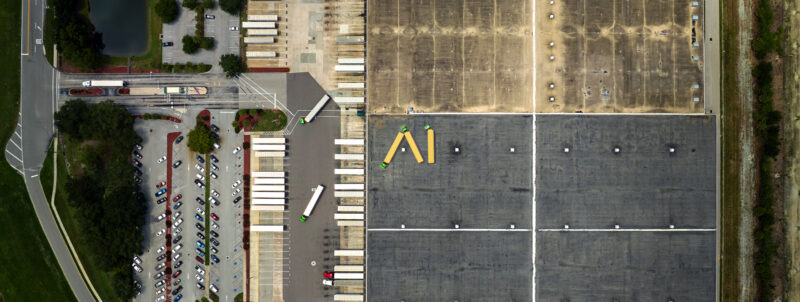

Implement AI for Inventory Optimization

Artificial intelligence (AI) helps predict demand fluctuations, optimize stock levels, and recommend replenishment strategies. Leveraging AI to manage inventory can help reduce stockouts or excess during unpredictable weather conditions.

-

Utilize Predictive Analytics for Weather Forecasting

By analyzing historical weather data, these tools help forecast potential disruptions, allowing companies to prepare in advance with alternate routes, expedited shipments, or increased stock.

Bridgenext: Your Partner for Supply Chain Resilience

When preparing for hurricane season, having a reliable partner like Bridgenext makes all the difference. With deep experience in Transportation & Logistics, Bridgenext equips logistics leaders with cutting-edge digital solutions and data-driven services to strengthen supply chain resilience.

Key Solutions for Hurricane Preparedness

- AI-Powered Inventory Management: Bridgenext’s advanced AI Solutions for predictive analytics and inventory management solutions help businesses maintain optimal stock levels, even during supply chain turbulence.

- Data Analytics and Real-Time Tracking: Real-time tracking and data analytics provide logistics leaders with the visibility needed to make informed decisions.

- Customized Business Solutions tailored to meet the unique demands of diverse industries.

Building a Future-Ready, Resilient Supply Chain

Preparedness is the cornerstone of supply chain resilience. By combining forward-thinking strategies with innovative solutions, businesses can confidently face the challenges of hurricane season and continue to meet customer demands without sacrificing efficiency.

Navigate Hurricane Season with Confidence

The unpredictable nature of hurricanes underscores the need for careful planning and advanced tools to protect supply chains. Through proactive preparation and partnerships with trusted solution providers like Bridgenext, logistics leaders can navigate disruptions confidently, ensuring continuity and success in even the most challenging conditions.

Talk to us before the next disruption hits your bottom line.